|

Environmental standard proposal

|

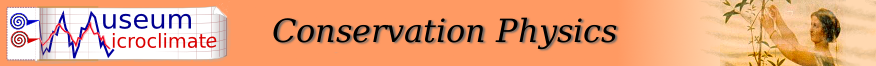

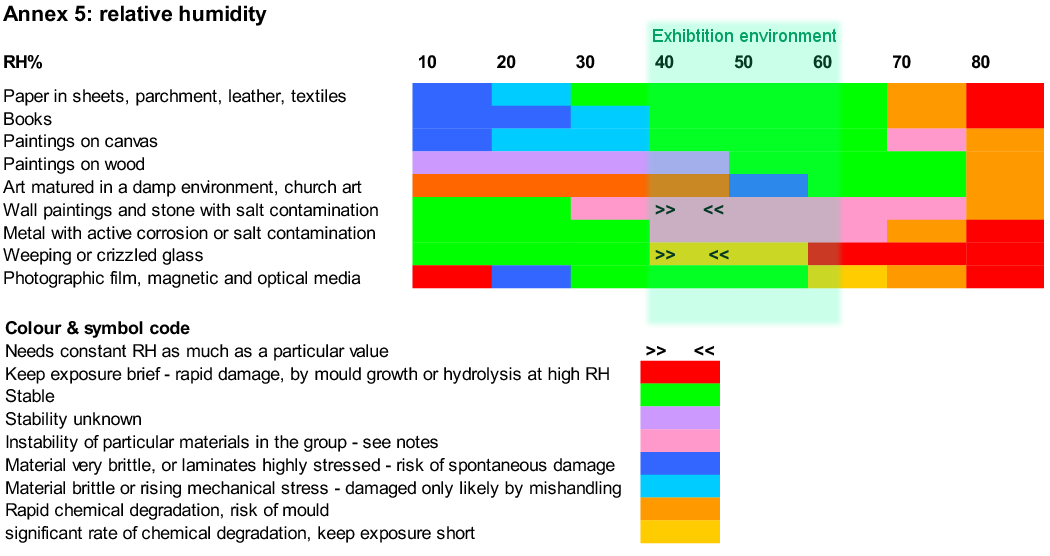

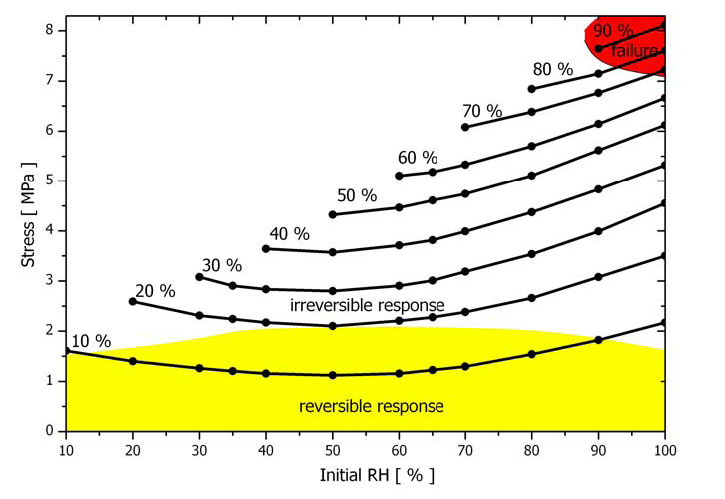

Relative Humidity (RH)Introduction to the RH recommendationsConstancy of RH has long been regarded as an important preservation measure. A precautionary attitude to specification has been a powerful influence favouring installing the best available technology, which is full air conditioning with humidification, dehumidification and pollution filtration. Given air conditioning, it has been taken for granted that one aims also for constancy of temperature, taking no account of the changing seasons outside. A consequence of this tradition is high energy consumption and damage to museums in cold winters due to condensation within the outer envelope of water from warm, humidified indoor air. [Padfield, T. 'The role of absorbent building materials in moderating changes of relative humidity', PhD thesis, Department of Structural Engineering and Materials, Technical University of Denmark,Report R-54 1999. ISBN 87-7740-256-1. pages 138-143. http://www.conservationphysics.org/phd/ch6.pdf ] There is also humidity induced damage to artifacts close to outside walls, caused by uneven temperature arising from the large difference between indoor and outdoor temperature. Such scientific evidence as we have suggests that a RH below 25%, even for a short time, is likely to cause splitting and flaking of laminated materials of differing hygroscopicity. A period of weeks above 75% RH is likely to cause mould growth on nutritious surfaces. [G. Ayerst, 'The effects of moisture and temperature on growth and spore germination in some fungi'. Journal of Stored Products Research'', Volume 5, Issue 2, August 1969, Pages 127-141 doi:10.1016/0022-474X(69)90055-1]. Some materials and laminated structures need a narrow RH range. However, the most important guide to the correct RH is often the history of the individual item. Paintings which have matured for centuries in the cool damp of a northern church cannot endure the 'ideal' museum climate recommended by standards. [Padfield, T.'The role of standards and guidelines: are they a substitute for understanding a problem or a protection against the consequences of ignorance?', in: Durability and Change, Edited by Krumbein, W. E. et al. Wiley 1994, pp191-99. http://www.conservationphysics.org/tim/cfys/ppubs/dahlem.pdf ] The wide ranges permitted in this section do not imply that such a large variation in a single place is safe. The message is that setting the RH range for a mixed collection is not a suitable subject for a stringent numerical standard. ExhibitionRH rangeFor existing buildings: no upper limit is defined. The lower limit is 25% For new build or deep renovation the design target should be within the range 65% to 35% with variation within this range restricted to a smooth yearly cycle. There is no universally applicable upper limit for RH, since a limit implies the capability for dehumidification and thus forces air conditioning. The lower limit at 25% may necessitate humidification in extreme winter weather. For new buildings and deep renovation the design target is attainable without air conditioning but may require dehumidification or humidification in some climatic regions. Consult the notes below to identify materials with finer limits for stability. These may need to be enclosed in showcases. Rate of change of RHThere is no specification for rate of change. For some items, such as oil painting on wood, a rapid excursion of RH has no effect, while a slow move even to a moderate value can yet be catastrophic. Materials do not necessarily adapt to slow change of RH. Frequent extreme change of RH will wrinkle textiles and paper and will decompose paper [Bogaard, John, Whitmore, Paul M.,'Explorations of the role of humidity fluctuations in the deterioration of paper'. Works of art on paper: books, documents and photographs: techniques and conservation: contributions to the Baltimore Congress, 2-6 September 2002 (2002) pp 11-15] RH uniformityThere is no specification for RH uniformity. There is no specification because if the temperature is uniform, as specified in the temperature section, the RH will also be uniform, assuming there are no building defects. Generally the water vapour concentration is more constant than the temperature throughout a contiguous exhibition or storage space, so temperature variation is the main cause of RH variation on a short timescale of a few hours. RH in exhibition showcasesFor humidity sensitive items which are enclosed to separate them from the variable RH in the exhibition space, the RH should not vary more than ±10% from the annual average in the showcase. Normally, the annual average within the case will be identical to that in the room. If the showcase is actively conditioned to a RH different from the annual average in the room the same limit applies, enforcing careful monitoring of the showcase RH. Humidity buffering and airtight design make this specification attainable. There should be no need for intermittent regeneration of the buffer except in the case that the item requires a constant RH different from the annual average in the enclosing space. RH in storageIn existing storage the RH may vary between 65% and 35%. In new build or deep renovation, the RH must keep within ±5% of the annual average in the store. This average may be set between 65% and 35% according to the predominant materials and assemblages in store. In a newly built store, airtightness and humidity buffering can combine to give a very stable RH [Ryhl-Svendsen et al, 'Ultra low energy museum storage', icom-cc-lisbon 2011 in press]. The average RH can be adjusted either by heating above ambient or by dehumidification, often by a combination of the two methods. In an existing store the RH can be kept within the specified limits by heating combined with airtight bagging of stored items. RH in cold storageThe target constant RH may be set at any value between 35% and 50%. The RH must be held constant to ±5%. The influence of RH on chemical degradation is much reduced in cold storage because the low temperature inhibits reaction very effectively. Therefore the minimum RH is set relatively high to minimise the risk of delamination of composite items whose components will be stiffer on account of the cold. At equilibrium with a given RH, cold items will have a higher water content than the same item warm. When items are retrieved into a warm place they will have the water content characteristic of a higher RH. This is why the maximum RH in the cold store is set rather low. RH during transportThe RH under transport shall be within ±5% from the specified target, which is chosen according to the information in appendix H. A combination of temperature stabilisation by insulation and a reflective outer skin to the package gives the necessary temperature uniformity within the container. A small amount of humidity buffer close to the item will then maintain a constant RH due to the small amount of air and the small air exchange rate. Note that the buffer must be at the same temperature as the item being protected, so protection against heat penetration is very important. NotesIntroduction to RH sensitivitiesThe RH is identical to the chemical concept of water activity - the potential for water to enter into reaction, both chemical and dimensional through water molecule adsorption. As a general rule the chemical addition of water, known as hydrolysis, has a rate proportional to the RH. Hydrolytic degradation is a very common pathway in organic materials but is usually slow in museum artifacts. Exceptions are listed below. If the item can withstand, or is immune to, dimensional stress, a low RH is to be preferred. Dimensional change, combined with increasing stiffness at low RH, is the main cause of sudden failure of museum objects. It usually shows as delamination, flaking and splitting. Deliquescence and recrystallisation of salts when the RH passes through a critical value is a common cause of physical damage in museums. The critical value is specific to individual ionic salts [Waller, op cit in the temperature section]. Deliquescent salts, often as invisible surface films, greatly accelerate the vast majority of metal corrosion reactions by providing an ionising solvent.  Materials subject to rapid hydrolysisCellulose acetate decomposes fast by autocatalytic hydrolysis. In museums the process is always delayed by cold storage rather than by reducing the RH. This is because cellulose acetate was a commonly used film base laminated to a hygroscopic gelatin layer. Low RH will make the gelatin brittle and likely to separate from the film base. Hydrolysable polymers have been widely used for everyday items. A low RH is not helpful for preservation because plastics also decay by other mechanisms, notably loss of plasticiser. Cold storage is the correct preservative measure. For exhibition, one must expect an unpredictable durability for plastic items. The iron sulfide minerals pyrite and marcasite, as specimens but also as constituents of fossils and excavated wood, oxidise to form deliquescent acidic liquid which promotes further decomposition. A RH below 30% is recommended [Howie, F. M. P. 1977. Pyrite and conservation part 1: historical aspects. Newsletter of the Geological Curators Group 1:457-465] Bronze and iron contaminated with chlorides may decompose fast and need lower RH than 35%. On the other hand bronze with a chloride containing patina may be stable for ever. Metal corrosion figures large in the scientific literature, so will not be treated in further detail here. Materials and constructions sensitive to dimensional changeOil paintings on canvas should be kept below 65% as some canvas weaves shrink forcibly at high RH [Karpowicz, A., In-plane deformations of films of size on paintings in the glass transition region, Studies in Conservation 34 (1989) 67-74] Oil paintings on wood should be kept at a RH close to their historic environment. Tenting of paint over wood is characteristic of paintings removed from damp buildings for 'better' preservation in museums. Wooden musical instruments require a constant RH to maintain their tuning. Note that the bores of woodwind instrument rapidly attain 100% RH when played, with measurable distortion of the profile and permanent drift in tuning, so museum instruments should not be played. For rare scholarly research into their performance, slow pre-conditioning to 80% RH is mandatory. Veneered furniture should be kept above 40%, since it was mostly made from air seasoned wood in equilibrium with around 60% in a workshop with high humidity. Ivory splits below 25% Wood reacts anisotropically to change of RH, this causes splitting. For the safe RH range, consult the paper by [Koslowski ... ]  Deliquescent and phase changing mineralsWater soluble minerals, which are common contaminants of museum objects, are a potent cause of damage. The RH ranges over which minerals change phase or liquify are listed by [Waller op.cit (under temperature)]. It is generally not practical to identify these contaminants, and mixed ionic composition gives variation in the deliquescence point, so it is convenient just to ensure a constant RH, whatever it may be. Mould growthThe limiting RH for mould growth depends on the temperature and the nutritiousness of the surface.  Limits for mould growth according to Martin Krus [Ralf Kilian, Martin Krus and Klaus Sedlbauer, Assessment of Mould Growth and Moisture-Related Damage to Indoor Cultural Heritage via Simulation with a Whole Building Model.' The Object in Context: Crossing Conservation Boundaries: Contributions to the Munich Congress 28 August – 1 September 2006 (2006) pp 336-336]. Insect damageInsects need water but some make water by digesting carbohydrate food. Insects do not thrive below 50%. Serious infestation requires a high RH or access to liquid water. Take care that there is not intermittent condensation on windows or access to the water traps of floor drains. A reliable inhibitor of insect infestation is a low temperature. The interaction of temperature and relative humidity In a moisture-inert space, the relative humidity will automatically fall as the temperature rises. This applies even to well ventilated interiors. Exhibition galleries are usually moisture inert, having objects in glass cases, varnished or mineral floors and painted walls. At the opposite extreme, a tightly packed paper archive will show a small rise in RH as the temperature rises. The paper buffers the space around it by evaporating water. A complication arises when there are such buffer materials in a showcase or a transport case. One might imagine that a humidity buffer is automatically beneficial in stabilising the RH. This is true if the buffer is always at the same temperature as the artifact it is presumed to protect. If there is a temperature difference between the artifact and the buffer, the buffer will stabilise the RH at its surface temperature. This combination defines the water vapour content, which will even out rapidly throughout the enclosure. The RH around the artifact will then be defined by the water vapour concentration and the (different) temperature. This difference in RH will be stable, as long as the temperature difference remains. This process is nearly always the cause of mould growth in unventilated corners of rooms containing buffer materials. The material buffers the RH to a moderate value at its temperature. The unventilated corner is colder, usually because of poor thermal insulation in the outer wall. The RH is therefore continuously higher. This is why the standard sets a limit for temperature difference in space, rather than an allowable variation in time. This requires more measuring devices spread around the room. However, it is only necessary to measure temperature in most places, since experience shows that the water vapour concentration is uniform throughout rooms. |