|

The reaction of wood to moisture - 2 |

Wood is generally considered the sinner when the surface coating flakes off as a result of a change of relative humidity. The situation is, however, complicated by the great dimensional stability and stiffness of wood in the axial direction, along the length of the fibres.

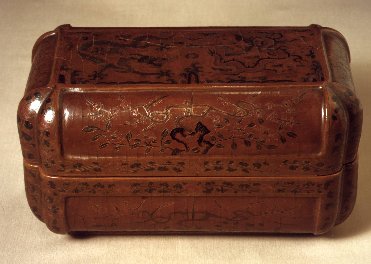

Chinese lacquer is applied at high RH, to speed the hardening of the resin. When the finished lacquer box (about 250mm long) is allowed to come to equilibrium with the modern temperate indoor climate, the lacquer layer will loose water and try to shrink. Stress develops in the lacquer layer. It is relieved, or even reversed, by the shrinkage of the underlying wood as it also dries out. Along the grain, however, the wood hardly shrinks at all and so the lacquer cracks across this direction of maximum stress.

Chinese lacquer is applied at high RH, to speed the hardening of the resin. When the finished lacquer box (about 250mm long) is allowed to come to equilibrium with the modern temperate indoor climate, the lacquer layer will loose water and try to shrink. Stress develops in the lacquer layer. It is relieved, or even reversed, by the shrinkage of the underlying wood as it also dries out. Along the grain, however, the wood hardly shrinks at all and so the lacquer cracks across this direction of maximum stress.

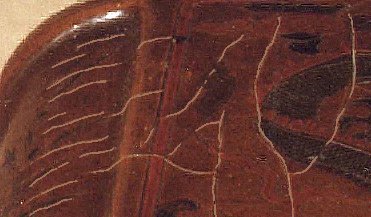

The lines of the cracks have been emphasised in this close-up. Notice that the cracks change orientation on the curved part. The pattern reveals the construction of the box. The cracks are always across the grain.

The lines of the cracks have been emphasised in this close-up. Notice that the cracks change orientation on the curved part. The pattern reveals the construction of the box. The cracks are always across the grain.

It is more usual to see damage caused by the opposite situation, where the wood moves more than the decorative finish. The characteristic damage pattern is displayed by this church altar picture (about 1.5m across), brought to a conservation workshop for treatment. It was carefully wrapped to spread over several months the change from equilibrium with approximately 80% RH, that it had been accustomed to since the 16th. century, to the 55%RH of the workshop. Even with this precaution the brittle paint layer was compressed into tilted tiles as the wood shrank beneath it. The cracks in this case are predominantly parallel with the grain of the wood.

It is more usual to see damage caused by the opposite situation, where the wood moves more than the decorative finish. The characteristic damage pattern is displayed by this church altar picture (about 1.5m across), brought to a conservation workshop for treatment. It was carefully wrapped to spread over several months the change from equilibrium with approximately 80% RH, that it had been accustomed to since the 16th. century, to the 55%RH of the workshop. Even with this precaution the brittle paint layer was compressed into tilted tiles as the wood shrank beneath it. The cracks in this case are predominantly parallel with the grain of the wood.

This close-up, about 50mm across, shows the overlapping paint flakes with the dominant cracks parallel to the grain of the wood. There is also a hint of breaks lying across the grain, probably caused, as with the lacquer box, by shrinking of the paint over the stable direction of the wood.

This close-up, about 50mm across, shows the overlapping paint flakes with the dominant cracks parallel to the grain of the wood. There is also a hint of breaks lying across the grain, probably caused, as with the lacquer box, by shrinking of the paint over the stable direction of the wood.

When museum objects are only subjected to slowly changing RH, the damage caused by the different reactions of materials which are laminated together cannot be entirely avoided, as our experience with the altar picture shows. The damage is, however, reduced, because materials slowly relieve stress by rearranging their internal structure. This process is called stress relief and was mentioned in an earlier chapter "Stress, strain and Craquelure". Stress relief occurs in materials held at constant size and it is not therefore noticeable. If the material can move under the applied stress the process is called creep. Stress relief and creep are two expressions of the same underlying process. The rate at which wood absorbs and desorbs moisture is an important factor in determining the risk of damage.

This work is licensed under a Creative Commons Attribution-Noncommercial-No Derivative Works 3.0 License.